In 1854, Louis Vuitton, now a namesake fashion house, set up his first shop near Place Vendôm on a small street by the name of rue Neuve-des-capucines in Paris. However, it wouldn’t be until 2013 that the brand revived the now-famous street of Vuitton’s first workshop and boutique to introduce its iconic line of handbags, the Capucines.

Known for its rich pedigree in travel and luggage, the fashion house’s Capucines bag takes inspiration from the brand’s roots by marrying elegance with utility. Arguably their most low-profile, the bag is a departure from Louis Vuitton structured valises, sporty satchels, or monogrammed canvas wallets. With its subdued ornamentation and roundness, and soft but structured design, the Capucines adds to the growing archive of leather handbags in production at Louis Vuitton since 1880.

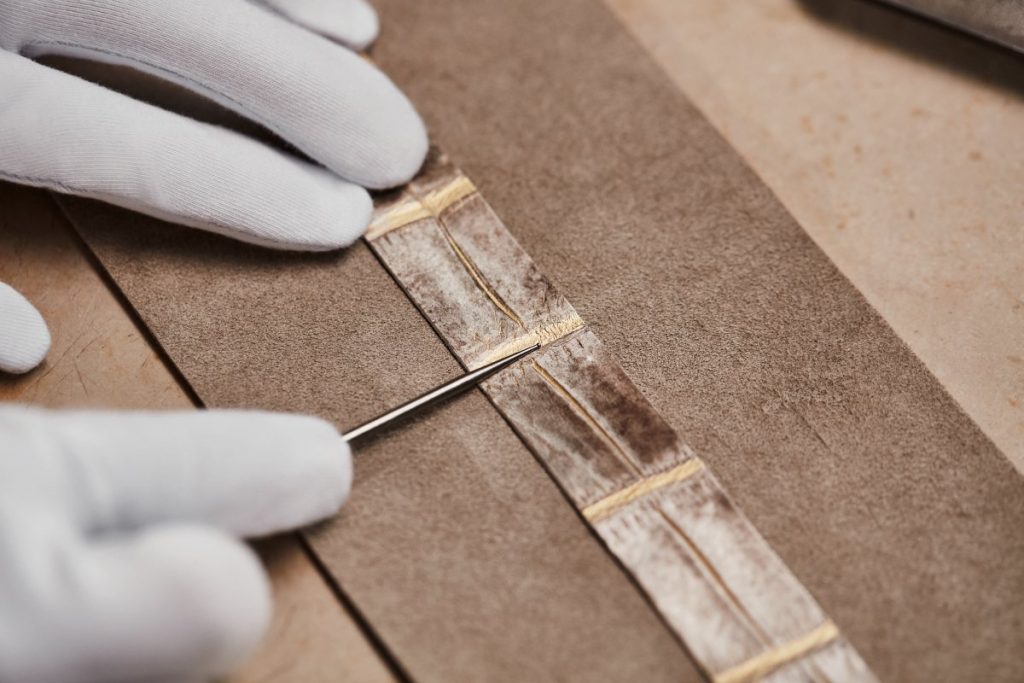

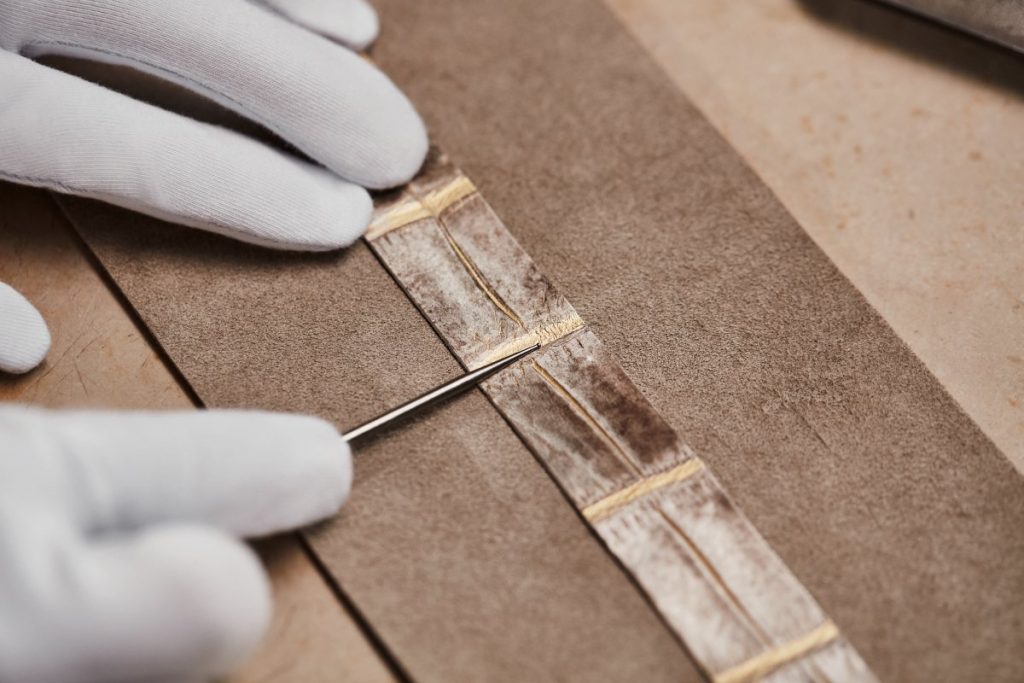

The Capucines takes inspiration from the brand’s commitment to savoir-faire, which translates to “know-how” and stands for the company’s concept of exquisite atelier craftsmanship. Requiring over 250 hand-crafted steps, watchful leather artisans take the product from skin to bag in one week, but it takes years to master the semi-rigid handle stitching, or the signature twin rings with hammered-in studs.

RELATED: Louis XIII Launches Its Latest Campaign with a Nod to Musical Excellence

Built in a four-step process beginning with full grain taurillon leather skins dyed in a spectrum of colours ranging from cream and black to cobalt and Fuschia, each of the skins arrive at the modern atelier in Sarras, France from Spain, Italy, or northern Europe, where a team of 250 craftsmen begin their work.

Alongside the craftspeople exists the time-tested equipment inside the building—a machine for stamping stud holes, a well-used wooden workbench featuring a functional belt made of leather, and all the tools to work on the raw materials to produce the Capucines. Meticulous in detail, every material must be checked. Craftspeople gauge the softness, colour, scars, wrinkles, and evenness of grain, with a machine ensuring optimal thickness. The top fragile layer of skin, known as croûte, peels off in the tannery while what is left, the fleur, remains between two to 2.4 millimetres thick.

After ensuring the refinement of the leather, it is off to crafting the bag. The atelier in Sarras highlights the intersection between classic and modern, with computers replacing paper and chalk to assemble the leather’s optimal cutting pattern. However, it’s the craftsman who ensures the front and back match perfectly in colour before moving to teams of six to ten people working on each handbag’s Spanx—a word meaning the invisible elements which ensure proper silhouette.

To remedy the undyed leather edges, careful hands hold the edges against a machine that applies a clear base, shapes it to a rounded profile, and applies a custom blend. After being air dried twice, Louis Vuitton uses burning iron to shore oil to the leather’s surface (known as the Filetage technique) as added protection. This process is hard to replicate and takes years to master.

The latest model is called the BB (Pronounced bébé in french and is short for Brigitte Bardot), and is small enough to double as an evening bag with a removable bandolier-style strap. With interior soft canvas, and jewel-like rings connecting the handle to the bag, the finishing details highlight the brand’s commitment to luxury and prestige. When all is said and done, the bag is meticulously viewed by quality control, a repetitive job given the artisan’s talent and diligence.

Earlier this year, Louis Vuitton increased production of its exotic skins and ultra-luxury handbags following global price increases. At a time when exotic skins in luxury have faced criticism with alternative leathers becoming more popular, Louis Vuitton sees the gap in the market for exotics skins “done responsibly.” By the end of 2022, the brand has committed to 100 percent of crocodile skins used for handbags to come from farms certified by the Crocodile Standard, which underscores four key pillars—the preservation of the species, animal welfare, environmental protection, and respectful working conditions. With the majority of Louis Vuitton’s bags being produced in a bespoke manner with certification standards, the brand took the route of sustainable sourcing, with parent company LVMH announcing their plans in 2019.

Already considered a classic by Louis Vuitton, the Capucines is a masterclass in fine craftsmanship.

[yikes-mailchimp form=”1″ title=”1″ submit=”SUBSCRIBE”]